Assemblies in Allocadence are for a “Build To Stock” scenario, where you prepare the new finished product in advance of any orders for it. For product kits/bundles that are “Built To Order” instead and are assembled during the fulfillment process rather than in advance, use our Kit feature instead.

The “Assemble Now” feature allows for a simple one-step assembly process, where the assembly is started and finished in one session by a single user. If your need is for a two-step assembly process where work orders are tracked, use Create an Assembly Work Order instead.

Creating an assembly without a work order

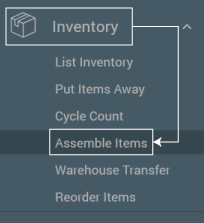

- Begin at the Inventory section and select “Assemble Item” in the submenu.

- Search for the specific item you would like to build by entering the SKU or Description into the “Items to Assemble” field.

- Choose a quantity of the assembly to build. Next click “Assemble Now“.

- A work order will print the list of components needed along with their location, and the assembly is considered complete. Inventory is deducted for the components and inventory is added for the new finished product(s) automatically.